The primary purpose of PCB surface treatment is to ensure reliable solderability and maintain excellent electrical performance. Copper, when exposed to air, tends to oxidize over time, forming copper oxides that can hinder soldering and reduce conductivity. To prevent this, various surface treatments are applied to protect the copper surfaces and ensure long-term functionality.

1. **Hot Air Solder Leveling (HASL)**

Also known as spray tin, HASL involves coating the PCB with molten solder and then using hot air to level the solder across the board. This process creates a protective layer that prevents oxidation and enhances solderability. During the process, the PCB is submerged in molten solder, and an air knife removes excess solder before it solidifies. This minimizes solder bridges and ensures a smooth, even finish.

2. **Organic Solderability Preservative (OSP)**

OSP is an environmentally friendly surface treatment that complies with RoHS regulations. It forms a thin organic film on the copper surface, offering protection against oxidation, moisture, and thermal stress. The film is designed to be easily removed by flux during soldering, allowing clean copper to bond quickly with molten solder, ensuring strong and reliable joints.

3. **Full Plate Nickel-Gold Plating**

This process involves depositing a layer of nickel followed by gold onto the PCB’s conductive areas. The nickel acts as a barrier to prevent diffusion between gold and copper. There are two types: soft gold, used for wire bonding in chip packaging, and hard gold, which is more durable and suitable for high-wear applications like connectors.

4. **Immersion Gold (ENIG)**

Immersion gold involves applying a thick layer of nickel-gold alloy to the copper surface. This provides long-term protection and is particularly beneficial for lead-free assembly. It also helps prevent copper dissolution, making it a popular choice for high-reliability applications.

5. **Immersion Tin**

Tin plating is widely used because most solder alloys are based on tin. Immersion tin forms a flat intermetallic layer between copper and tin, offering good solderability without the issues associated with hot air leveling. However, the tin layer has a limited shelf life and must be assembled promptly after application.

6. **Immersion Silver**

Silver is a middle ground between organic coatings and electroless nickel/immersion gold. It offers good solderability even under harsh conditions but lacks the mechanical strength of nickel-based finishes. While it maintains its solderability, silver may tarnish or lose luster over time.

7. **Chemical Nickel Palladium Gold (CNPG)**

This advanced process uses palladium as a barrier between nickel and gold. The palladium layer prevents corrosion from displacement reactions and prepares the surface for gold deposition. The gold layer provides a stable and conductive contact surface, making it ideal for high-performance electronics.

8. **Electroplated Hard Gold**

Hard gold plating is used to enhance wear resistance and improve the durability of contacts. It is especially useful in applications requiring frequent insertions, such as connectors and edge cards. The addition of elements like cobalt makes the gold harder and more resistant to wear.

Lead Free Piezoelectric Elements

Â

The Co-Al Co-doped Barium Titanate Lead-free Piezoelectric Ceramics was successfully developed by Yuhai company through repeated experiments. By Researching the influence of Co-Al Co-doping on the structure and properties of Barium Titanate-based piezoelectric ceramics, the formulation and preparation technology of Barium Titanate-based piezoelectric ceramics were optimized. Yuhai`s BaTiO3 was prepared by conventional solid-phase sintering method, with the piezoelectric constant d33 (>170pC/N), dielectric loss tgδ≤0.5% and mechanical coupling coefficient  Kp≥0.34.

Barium titanate lead-free piezoelectric ceramics are important basic materials for the development of modern science and technology, which was widely used in the manufacture of ultrasonic transducers, underwater acoustic transducers, electroacoustic transducers, ceramic filters, ceramic transformers, ceramic frequency discriminators, high voltage generators, infrared detectors, surface acoustic wave devices, electro-optic devices, ignition and detonation devices, and piezoelectric gyroscope and so on.

Application:Â ocean, fishery, scientific research, mine detection, daily life and other fields.

Â

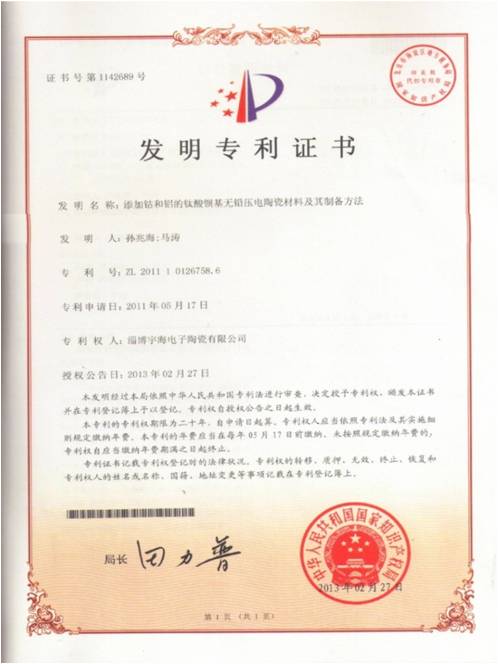

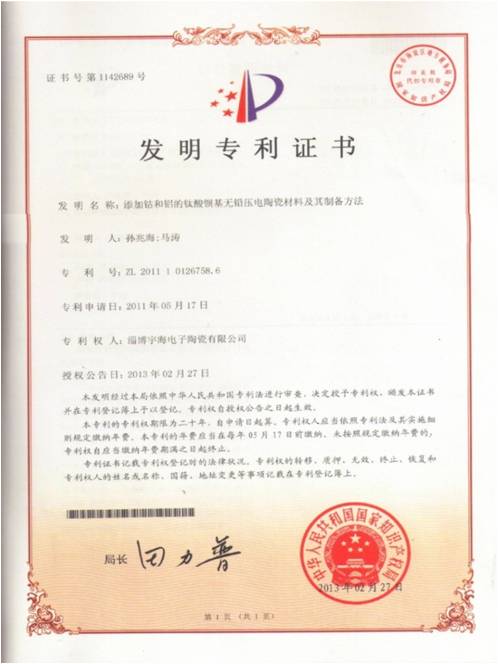

China Patent of Yuhai company`s BaTiO3

Chinese Patent No.: ZL 2011 1 0126758.6Â Â Â

Name: Lead-free Barium Titanate Piezoelectric Material with Addition of Cobalt and AluminumÂ

Â

Â

|

Lead free piezo material BaTiO3

|

Lead-free Material

|

|

Properties

|

Â

|

Â

|

BaTiO3

|

|

Dielectric Constant

|

ɛTr3

|

Â

|

1260

|

|

Coupling factor

|

KP

|

Â

|

0.34

|

|

Â

|

K31

|

Â

|

0.196

|

|

Â

|

K33

|

Â

|

0.43

|

|

Â

|

Kt

|

Â

|

0.32

|

|

Piezoelectric coefficient

|

d31

|

10-12m/v

|

-60

|

|

Â

|

d33

|

10-12m/v

|

160

|

|

Â

|

g31

|

10-3vm/n

|

-5.4

|

|

Â

|

g33

|

10-3vm/n

|

14.3

|

|

Frequency coefficients

|

Np

|

Â

|

3180

|

|

Â

|

N1

|

Â

|

2280

|

|

Â

|

N3

|

Â

|

Â

|

|

Â

|

Nt

|

Â

|

2675

|

|

Elastic compliance coefficient

|

Se11

|

10-12m2/n

|

8.4

|

|

Machanical quality factor

|

Qm

|

Â

|

1200

|

|

Dielectric loss factor

|

Tg δ

|

%

|

0.5

|

|

Density

|

Ï

|

g/cm3

|

5.6

|

|

Curie Temperature

|

Tc

|

°C

|

115

|

|

Young's modulus

|

YE11

|

<109N/m3

|

119

|

|

Poison Ratio

|

Â

|

Â

|

0.33

|

Â

Â

Piezo Element,Piezo Ceramic Elements,Piezoelectric Ceramic,Pzt Tubes

Zibo Yuhai Electronic Ceramic Co., Ltd. , https://www.yhpiezo.com